How to choose the most suitable battery charger?

Awareness on environmental protection has risen recently and the high-pollution petrochemical power has been gradually replaced by batteries that convert into electrical power; governments from different countries have also proposed different types of incentives to promote the flourishing development of various devices based on environmental protection (battery) power. Therefore, choosing a suitable charger for these devices is the key for equipment manufacturers to let the devices operate for longer periods of time. Simply put, a charger refers to a type of static converter that uses electric electronic semiconductor devices to convert voltage and alternating current with fixed frequency to low voltage direct current. Chargers supply electricity to batteries directly, and its built-in control circuits protect batteries from overcharge/over-discharge.

There are certain factors that need to be considered carefully before purchasing a battery charger in order to prevent the battery of devices from malfunctioning, or even damaging the device itself due to improper operations.

1.Confirm the input voltage acceptable to the battery charger

Make sure to check the input voltage before using battery chargers; if the input is higher than the voltage the charger can withstand, it may cause damages to the components inside the battery charger. The best battery charger design is the universal global voltage of 110-230Vac that is used in most countries; certain brands of charger products even use thoughtful wide input design to match the 85-265Vac voltage so that it can be used in all countries around the world. Such wide range AC voltage input allows consumers in countries with unstable power infrastructure and city grid to use charging devices safely.

2.Confirm battery type

Under most circumstances, battery chargers are unable to identify whether the battery to charge is lead-acid battery, LiNiCoMnO2 battery or lithium iron battery. Therefore when purchasing chargers, you must first understand which type of battery is used to supply power so that the battery wouldn’t be unable to be charged or get damaged. In addition, the output voltage of the charger must also match the battery so that the battery wouldn’t get damaged. A good charger can even have its charging curve modified according to the features of different batteries to provide more flexible options.

3.Decide the charging voltage, current, and charging time design according to the battery specifications

General battery modules are composed of 18650 lithium batteries as the core and connected using serial and parallel connections; if the battery module of the device is 10S (serial), 42V output chargers must be selected. If it is a 12S (serial) battery module, a 50.4V output charger must be selected to provide sufficient charging voltage. In addition, the current size of the charger will also affect the length of the charging time; take a 20AH battery for example, a 4A charger needs 5 hours to fully charge the battery but an 8A charger only needs 2.5 hours.

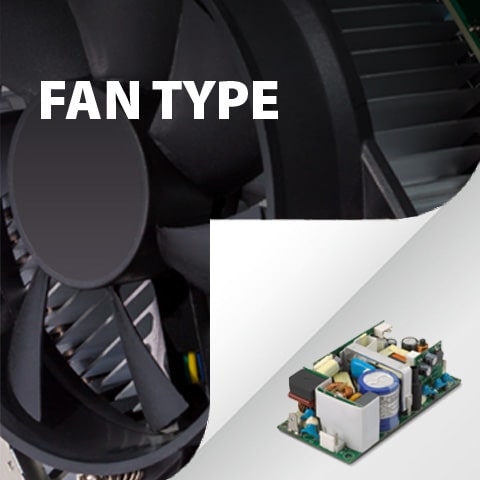

4.Cooling process and capability of the battery charger

Common cooling methods of battery chargers include fan-less natural cooling, air cooling design and water cooling design. Chargers with fan-less design can reduce the chance of malfunctioning due to accumulation of dust on the fan, but how to let the heat dissipate naturally without causing heat build-up and high temperature are challenges to the structural design of the product. Chargers with air cooling design use the operation of a fan to achieve cooling effects; its advantages include simple circuit and easy maintenance. Chargers with water cooling design have better cooling effects and no noise from fans compared to chargers that use fans for cooling. Consumers can choose the most suitable battery charger according to the usage environment requirements of the devices.

5.Confirm there is an appropriate charger port (connector) on the device

Before choosing a charger, make sure the specification of the DC jack matches the device to be charged so that it wouldn’t be unable to be charged. Some brands of battery chargers can even support the requirements of several battery management systems and also provide several types of DC jacks to satisfy the usage needs of different devices.

6.Equipped with safe charging mode and protection design

The most important function of a charger is to complete charging the device safely and efficiently; a good charger should be equipped with high charging efficiency, optimized charging curve design, complete charging modes (pre-charge mode, constant current CC mode, constant voltage CV mode and floating charging mode), complete charging protection designs (OVP, UVP, SCP, reverse polarity protection, charger OTP, battery OTP and timing protection) and meets corresponding safety regulations and EMC specifications.

For the six basic yet important focal points for purchasing battery chargers listed above, purchasers can set different conditions according to the terminal application to use it with and the battery module requirements. For example, application equipment that can be used with chargers can be roughly divided into mobile, on-board, and industrial types; based on the different application environments, chargers might require different levels of waterproof, shockproof and operating temperature ranges etc. When purchasers are choosing battery charger products, they must look for brands with professional R&D and manufacturing capabilities; not only does this provide another level of guarantee for safety, they will also have the ability to provide customized development services based on actual application needs.

Related Articles

-

Das bidirektionale Ladegerät USB Typ-C PD3.1 für Batteriesystemhersteller

-

FSP Power Solution GmbH bringt ein innovatives medizinisches 65W USB-PD Ladegerät auf den Markt

-

Steigern Sie Leistung und Stabilität mit fortschrittlichen CRPS-Stromversorgungslösungen von FSP

-

Neue Generation medizinischer Netzteile: FSP600M-70PB und FSP700M-70PB

About FSP

FSP Group is one of the global leading power supply manufacturer. Since 1993, FSP Group has followed the management conception “service, profession, and innovation” to fulfill its responsibilities as a green energy resolution supplier.